Products

Sulfur

In the form of lump and granular, sulfur is the chemical element most in demand because it is the starting material for sulfuric acid and a necessary byproduct of many chemical and industrial processes. Sulfur is a critical ingredient in many mineral fertilizers, including those based on phosphate, nitrogen, potassium, and sulfate. Non-ferrous metals, pharmaceuticals, farming pesticides, personal hygiene, cosmetics, and curing are just a few of the many other fields that benefit from sulfur’s many properties.

Granular sulfur

Granular sulfur is available in several shapes and sizes, including spheres, pastilles, and flakes. Granular fraction sizes can be modified through various technical approaches (0.5 to 6 mm). The purity level is 99.98 percent. Granulated sulfur has advantages due to the granulation process, which reduces the risk of dusting and pollution and enhances the durability and long-term stability of the product, all of which are essential considerations when shipping and storing the substance.

| Granular sulfur | |

|---|---|

| Sulfur | 99.98 |

| Moisture | 0.03 |

| Ash | <0.007 |

| Acidity | <0.001 |

| Organic matter | <0.005 |

Lump sulfur

One of the most common industrial forms of sulfur is lump sulfur, also called lump gas sulfur in the technical sense. There is an obvious benefit to producing lump sulfur, which is how easy it is to use. When liquid sulfur is filled into molds and allowed to solidify, the resulting chunks can be ground into lump sulfur.

Purity: 99.98%.

| Lump sulfur | |

|---|---|

| Sulfur | 99.98 |

| Moisture | <0.0059 |

| Ash | <0.002 |

| Acidity | - |

| Organic matter | <0.0037 |

Fertilizers

Ammonium nitrate

Using ammonium nitrate as a nitrogen fertilizer is essential during the growing season. Because of its high concentration of nitrate and ammonium nitrogen (about 34%), readily soluble in water and directly absorbed by plants, ammonium nitrate is a beneficial fertilizer. Ammonium nitrate can be used in any soil environment regardless of soil type or composition (clay, acidic, humus, etc.).

| Ammonium nitrate | |

|---|---|

| Nitrate and ammonium nitrogen | 34.4 |

| Water | 0.3 |

| pH | 5 |

MAP

Phosphate fertilizer is utilized mainly in the pre-planting phase because of its potency. The world’s dry regions have the highest phosphorus needs but the lowest nitrogen needs. Hence ammophos is widely used there. When used together, ammophos and ammonium nitrate promotes a yield increase of up to 40 percent.

| MAP | |

|---|---|

| Available phosphates | 46 |

| Nitrogen | 10 |

| Water | 1 |

Urea

The highest-concentration nitrogen fertilizer available, with nitrogen levels as high as 46%. Urea’s usable substance content per unit of measurement is several times larger than similar nitrogen-containing fertilizers, making it an economically good fertilizer. Its quick loss through evaporation from the soil also affects plant nitrogen intake in general. Therefore, its high volatility is something to keep in mind.

| Carbamide (urea) | |

|---|---|

| Nitrogen | 46.2 |

| Biuret | 1.4 |

| Water | 0.3 |

Petroleum coke

A dense carbon mass known as petroleum coke is produced when refining crude oil. Coke is utilized most frequently as an anode mass in the aluminum sector, and graphite electrodes are employed in the steel industry. Principal indications of petroleum coke quality include sulfur, ash, moisture, volatile compounds, and granulometric makeup.

CPC

Calcined petroleum coke is created by subjecting high-quality green coke to extremely high temperatures, which drives off any remaining moisture and hydrocarbons and leaves behind a dense carbon mass excellent for conducting electricity. Producing aluminum from raw bauxite ore requires the use of calcined coke. The percentage of carbon in it is more significant than 97%.

| GPC | |

|---|---|

| Sulphur | <2 |

| Ash content | <0.6 |

| Volatile matter | <13 |

GPC

A solid carbonaceous material, green petroleum coke is produced by coking refinery leftovers. Depending on its sulfur and metal concentration, raw coke can be used as a fuel or in creating anode mass.

| GPC | |

|---|---|

| Sulphur | <3.5 |

| Volatile matter | <12 |

| Ash content | <0.6 |

Bitumen

A tar-like solid material that is insoluble in water but can be dissolved in some organic solvents. We use open-pit and underground mining techniques to extract natural bitumens. Man-made varieties are made by refining natural resources like oil, coal, and shale.

Bitumen is crucial in creating asphalt concrete, asphalt-based roofing materials, and many other building applications. It has insulating properties and is used in the production of paint and varnish, and cable insulation.

Ores and concentrates

Manganese ore

The chemical and metalworking industries benefit from using manganese ore. Because of its helpful alloying and desulfurization properties, the manganese ore is a raw material for the metals industry. We have ore available with 20-45% manganese content and a 10-100 mm particle size.

| Manganese ore | |

|---|---|

| Manganese content | 20-45 |

| Fraction | 10-100 mm |

Copper ore

Copper ores have applications in the metallurgical and chemical industries. Copper’s low resistance and excellent heat exchange capabilities make it useful in various applications, including the creation of cable and wire goods and the creation of heat exchange apparatus.

Iron ore

Ores are rock deposits that contain significant amounts of iron. To obtain iron, which is used as a raw material in manufacturing carbon steels of varying grades, they are enriched in concentration plants.

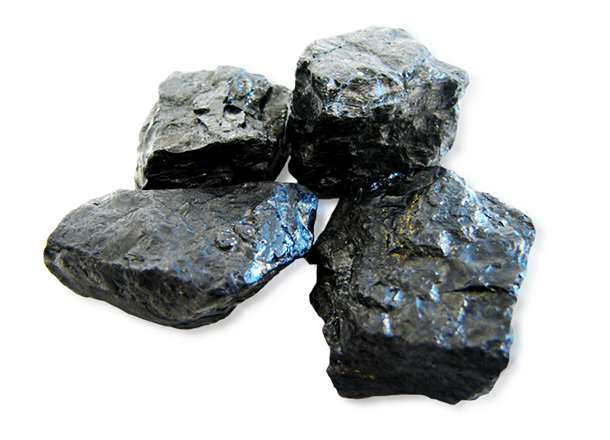

Coal

Given its high heating value, coal is in high demand among industrial users. Because it produces only a negligible amount of ash when burned, it is considered a relatively clean energy option. Coal is a versatile resource with multiple applications in industry, including as a fuel source and a raw material for creating a wide range of chemicals and end products.